Remote Toe Jack

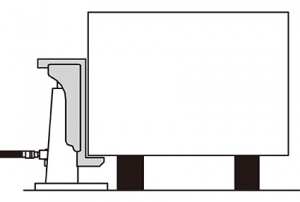

Remote toe jack is one type of toe jack which is connected with external pump (hand pump or electric pump) and hydraulic hose. It is possible to operate jack remotely for safety operation.

Remote toe jack is one type of toe jack which is connected with external pump (hand pump or electric pump) and hydraulic hose. It is possible to operate jack remotely for safety operation.

Features

- These hydraulic remote toe jacks are connected with an external pump and a high pressure hose.

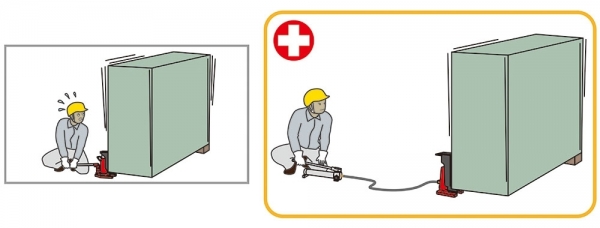

- Since operators can operate them remotely, in a small space or in a place where the foothold of machine is unstable, jacking up tasks can be safely completed.

- They can be lowered by the applied load and the speed to get down can be adjusted by controlling their valves.

- They can be operated with a small number of pumping.

- They can be laid on their side, tilted or placed upside down for many kinds of operation.

* Maximum working pressure: 60MPa

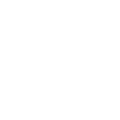

Operator can operate remotely

Conventional jacks require their operators to do jack-up operations right beside the machines to be jacked. Remote Toe Jack + Hand Pump enables its operator to remotely operate the jack-up from a safe place.

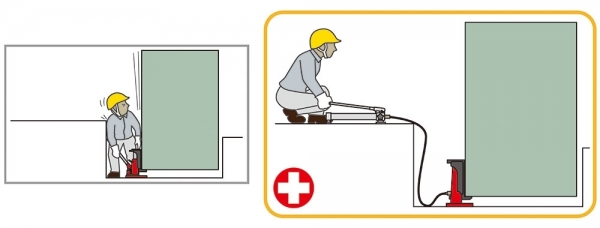

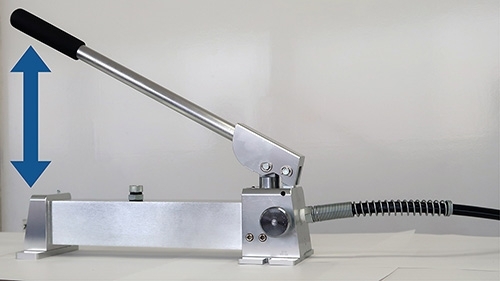

Reduce the time of operation

In case there is a gap between the toe of the jack and the contact point of the machine where its load is incurred, conventional jacks’ pump discharge speed is all the same regardless of the load, and therefore, it takes time to reach its load contact point. But Remote Type Toe Jack + Hand Pump have the two stage pump discharge, which enables the toe to reach its load contact point much faster and therefore, shortens its work time.

In case there is a gap between the toe of the jack and the contact point of the machine where its load is incurred, conventional jacks’ pump discharge speed is all the same regardless of the load, and therefore, it takes time to reach its load contact point. But Remote Type Toe Jack + Hand Pump have the two stage pump discharge, which enables the toe to reach its load contact point much faster and therefore, shortens its work time.

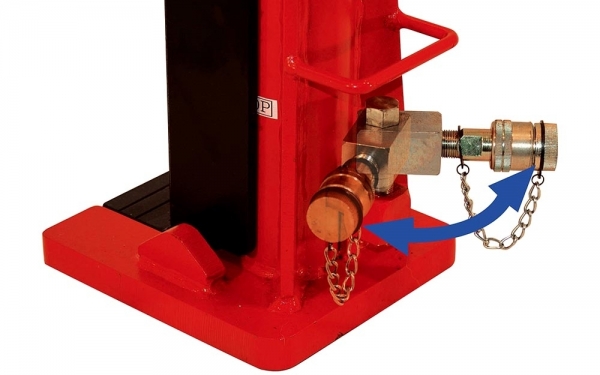

The coupler connection is a swivel joint

Since the coupler connection is a swivel joint, the high pressure hose can be prevented from breaking.

Since the coupler connection is a swivel joint, the high pressure hose can be prevented from breaking.

Specification

| Model | KS50-150 |

| Toe capacity | 5 ton |

| Head capacity | 9 ton |

| Minimum toe height | 22 mm |

| Stroke | 150 mm |

| Toe length | 55 mm |

| Toe width | 75 mm |

| Base width | 180 mm |

| Base length | 210 mm |

| Body height | 323 mm |

| Oil required | 239 cm3 |

| Product weight | 22 kg |

| Compatible with | APS05-60 |

| Download dimension drawing | |

| Model | KS100-150 |

| Toe capacity | 10 ton |

| Head capacity | 18 ton |

| Minimum toe height | 28 mm |

| Stroke | 150 mm |

| Toe length | 60 mm |

| Toe width | 100 mm |

| Base width | 230 mm |

| Base length | 250 mm |

| Body height | 363 mm |

| Oil required | 453 cm3 |

| Product weight | 41 kg |

| Compatible with | APS05-60 |

| Download dimension drawing | |

| Model | KS150-150 |

| Toe capacity | 15 ton |

| Head capacity | 26 ton |

| Minimum toe height | 38mm |

| Stroke | 150 mm |

| Toe length | 70 mm |

| Toe width | 100 mm |

| Base width | 245 mm |

| Base length | 300 mm |

| Body height | 395 mm |

| Oil required | 663 cm3 |

| Product weight | 62 kg |

| Compatible with | APS1-60 |

| Download dimension drawing | |

| Model | KS250-150 |

| Toe capacity | 25 ton |

| Head capacity | 43 ton |

| Minimum toe height | 38 mm |

| Stroke | 150 mm |

| Toe length | 70 mm |

| Toe width | 150 mm |

| Base width | 353 mm |

| Base length | 322 mm |

| Body height | 365 mm |

| Oil required | 1104 cm3 |

| Product weight | 88 kg |

| Download dimension drawing | |

| Model | APS05-60 |

| Maximum operating pressure at high pressure | 60 MPa |

| Maximum operating pressure at low pressure | 2 MPa |

| Discharge rate at high pressure (/stroke) | 1 cm3 |

| Discharge rate at low pressure (/stroke) | 12.9 cm3 |

| Effective oil | 500 cm3 |

| Body length | 512 mm |

| Body weight | 5 kg |

| Model | APS1-60 |

| Maximum operating pressure at high pressure | 70 MPa |

| Maximum operating pressure at low pressure | 2 MPa |

| Discharge rate at high pressure (/stroke) | 1.65 cm3 |

| Discharge rate at low pressure (/stroke) | 12.9 cm3 |

| Effective oil | 1,000 cm3 |

| Body length | 619 mm |

| Weight | 6 kg |

| Model | H2-SM-P |

| Body Length | 2m |

| Used with coupler | S-1H |

Parts List

Instruction Manual

Before work

|

1. Securely connect the high pressure hose and the remote toe jack with a coupler. |

|

|

2. Push the lever grip from the top with your hand to remove the lever hook. |

|

|

3. Turn the air valve counterclockwise to open. |

|

Jack-up operation

|

1. Turn the control valve clockwise and tighten it firmly by hand. |

|

|

2. Holding the lever grip with one hand and operating it up and down, oil is discharged and the toe rises. |

|

Jack-down operation

|

1. When the specified work is completed, slowly turn the control valve counterclockwise to open it. The toe descends as hydraulic fluid returns from the cylinder to the tank. |

|

After work

|

1. Turn the air valve clockwise to close it. |

|

|

2. Push the lever grip from above and fix the lever with the lever hook. |

|

|

3. After confirming that the toe lower to the bottom, disconnect the high pressure hose from the jack. Be sure to attach a duster cap to the coupler. |

|

Operating Manual

Safety Precautions

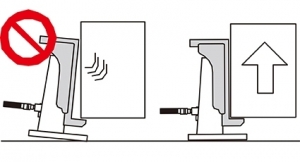

- In the process of jack operation, never expose any part of your body under a heavy load being handled. Fallen or overturned heavy load may cause serious injuries or even fatalities.

- When a heavy load needs to be jacked up and held, be sure to use proper means (trestles, sleepers, blocks, etc.) under it for safe and stable support. Supporting with jacks alone are pre-carious, and fallen or overturned heavy load may cause serious injuries or even fatalities

- Never use the jack at the condition exceeding its allowable load. If the jack is operated in overload, it may break and fallen or overturned heavy load may cause serious injuries or even fatalities.

- Install the jacks on a hard, level foundation in a stable manner. Never use the jacks on a slope or soft ground. The load may fall off or overturn.

- Be sure to put the toe fully under a heavy load to be lifted. By supporting the load only with the fore-end of the toe, the load may drop off or slant. The load may fall off or overturn

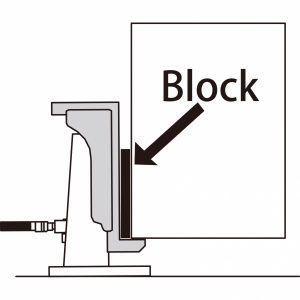

- If a clearance appears between a load and the leg of the toe, be sure to put a block at a proper size in between the load and the leg. If not, the load may fall down or overturn

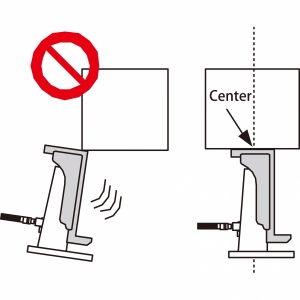

- When supporting a load on the ram head, be sure to support the load at the center of the ram head (head bolt position). If the load is off center, the jack may fall over and the load may fall off or overturn

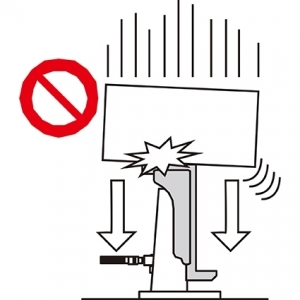

- Do not turn down the jack rapidly. The load may fall off or overturn

- Do not remove a coupler under load pressure. There is a danger that oil may spout out and get into your eyes

- Do not take hold with your hands the high pressure hose under pressure. In case that the hose gets damaged while you are touching the hose, the pressured oil jets out and creates the potential for serious injury to your hands.

- Never use the jack in the water, mud or sand. It will get damaged.

- Use the jack within the ambient temperature range of –10℃ to +55℃. In a colder environment, the oil will be frozen up, and the packing hardened. In a hotter environment, the oil and packing will expand. In either case, the jack will not work as designed and/or get damaged.

- Do not transport the equipment by dragging the high-pressure hose .

- Before connecting the coupler, clear away dust that adhere to the coupler. After usage, put duster cap on the coupler to prevent dust from mixing into the system.

- Make sure to connect the coupler to the root

- Do not connect or disconnect the coupler under pressure.

Daily Checklists

Before using

Check the following things before use, and if applicable, take measures such as sending them out for repair without using the jack or hand pump.

- When finding the jack/hand pump/high pressure hose if there is any oil leakage.

- When operation is not smooth due to lifting up/lowering to the stroke end with no load.

- If the toe/base of the jack is distorted and deformed.

- If the hose or coupler is scratched or damaged.

- When other abnormalities are found.

After using

After use, keep the following things and store it indoors at room temperature.

- Store the remote toe jack after its ram is returned to the bottom.

- Attach a duster cap to the coupler and lightly tighten the pump air valve before storing.

- If there is mud, sand, or other deposits on the jack/hose/pump parts, clean and store them.

- Do not store near fire or where it may be exposed to water or seawater